FAQs

How is the Technotill Seeding System different from other seeding systems?

The Technotill Seeding System places and packs seed, then sidebands fertilizer on each side of the seed row in a single pass. It is designed as a retrofit for airseeders and heavy duty cultivators.

How thick should the pack be, and what does it look like?

Usually, the pack is set at ¼ to ⅜ inch thickness. The pack is clearly visible. In clay soil, it is as firm as the seedbed. In lighter soil, it is less firm, but still clearly visible.

How do you set the pack thickness and packing pressure?

The bottom of the packer plate is raised or lowered using a nut on a threaded rod. In most cases the packing pressure and pack thickness are set in the same operation.

Spring compression can be estimated by measuring the length of the spring. The uncompressed spring measures 7.25 inches. According to manufacturer’s specifications:

1/2 inch of compression = 90 pounds spring pressure

1 inch of compression = 180 pounds spring pressure.

Actual pressure can vary slightly, depending on the shank movement

Where is the seed placed and how deep can you seed?

The seed is placed through the seed boot. Technotill recommends that the seed be placed into moisture soil. In limited moisture conditions, plan to seed slightly deeper to ensure enough moisture to support germination. In excellent moisture conditions, seed is generally placed 1-1.5 inches deep.

The pack thickness remains the same at any seeding depth. As seeding depth increases, expect that more loose soil will fall over the pack. This can be controlled, to some extent, through speed.

What kind of cultivators or air seeders can you put Technotill on?

Technotill requires a heavy duty tool bar, with a heavy-duty (minimum 1x2 inch) C-shank and heavy-duty (minimum 450 pound) trip mechanism.

Watch the video titled "Shank & Trip Requirements" in our video gallery

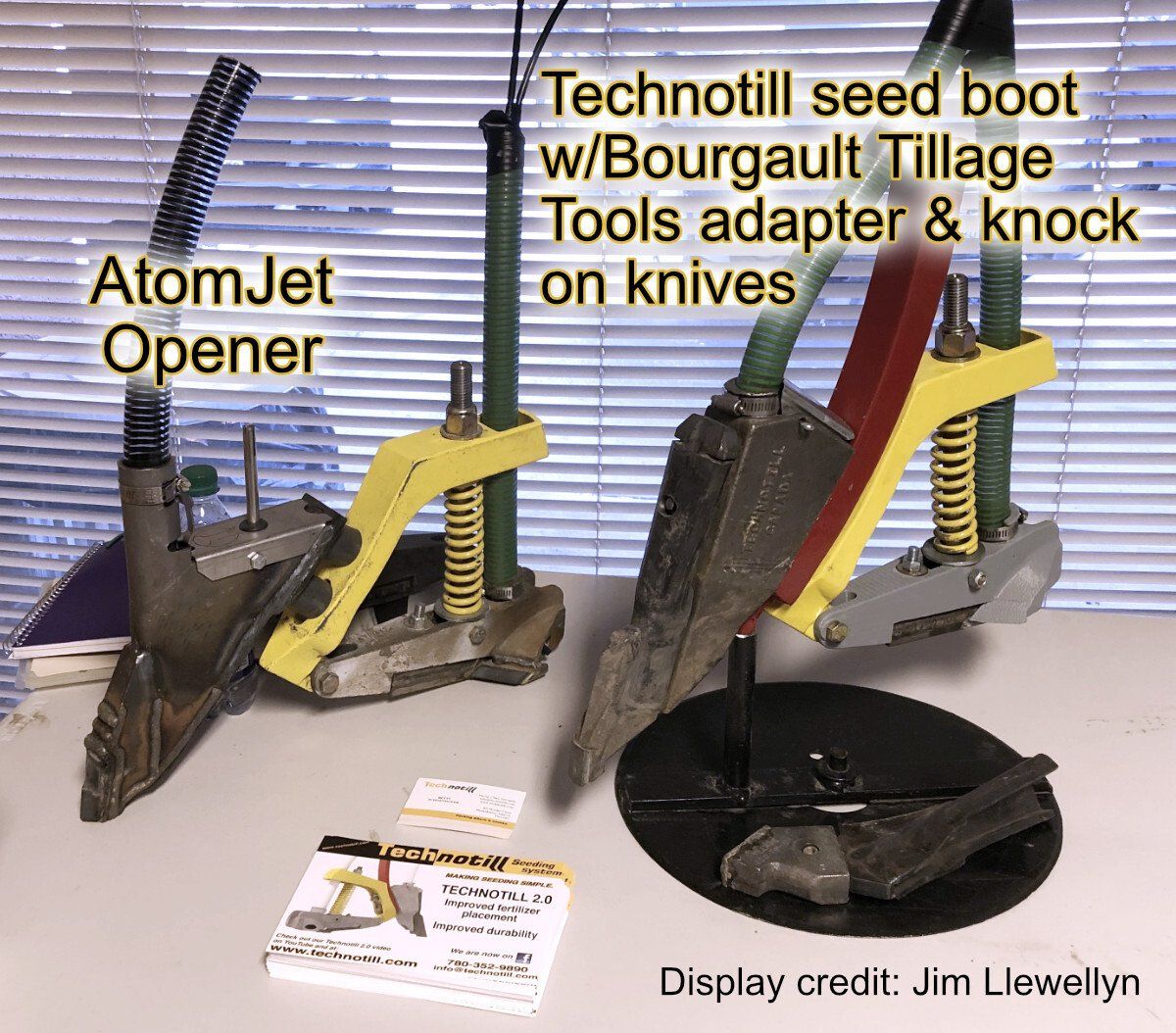

What kind of openers can I use?

Openers that work with Technotill must be low disturbance with front seed delivery.

We have dependable performance with two openers:

- AtomJet

- Technotill/Bourgault Tillage Tools combination which uses knock on knives

How long will the packer plates last?

Packer plate wear is expected to be similar to the wear on the carbide on the opener tip.

What kind of fertilizer can be used?

Dry, liquid or NH3 fertilizer can be side-banded on each side of the seed row.

Where is the side-banded fertilizer placement?

After the seedrow is packed, the fertilizer is sidebanded into the walls of the furrow. The fertilizer is placed the thickness of the pack higher than the seed, and approximately 1 ¼ to 1 1/2 inches from the seedrow.

What is Technotill’s warranty policy? What about repair or replacement parts?

All Technotill products are warranteed for the first year. Parts that fail will be replaced. Technotill carries a stock of replacement parts.

What horsepower requirement is necessary?

The Technotill Seeding System requires approximately 4 to 6 horsepower per shank. Additional horsepower for the tank depends on tank size.

Can fields be rolled after being seeded with Technotill?

Yes. We recommend that fields should be rolled in the same direction as the seed rows. The roller rides on the hump between the seed row, and does not seem to compact additional soil over the seed row.

What should I look for if I’m buying a used Technotill system?

Technotill is designed to be a durable system, but it doesn’t last forever! In addition, Technotill has improved the design of a number of system components: the yellow bracket which attaches to the shank, position of the fertilizer sideband, the packer plates, and the shank bolts. These improvements have improved durability, ease of installation, and performance.

Check the following:

- Wear on the packer plate. The plate should hang below the casting in which it is installed. If the packer plate is worn, the rear of the casting will be worn. In that situation, there is not proper packing of the seed row.

- Wear at the orifice. If the carbide wing is not intact, there will be significant wear on the casting, resulting in incorrect fertilizer placement.

- Wear on the packer hinge bolt.

- Wear on the opener. Check wear on the carbide tips, and the sides of the seedboot.

What maintenance needs to be done with Technotill?

Very little maintenance is required, but to maintain performance, we recommend:

Annually, before seeding:

- Check for wear on the packer plate, carbide wing in front of the fertilizer orifice, and wear on the packer hinge bolts, and roll pin.

- Check for wear on the opener: condition of the carbide tip, wear on the sides of the tip and on the seed boot.

- Check Speed Loc adapter to ensure that it is centred on the seed boot and that the bolts holding it to the seedboot are tight.

- Check that the shank bolts are tight.

- Check pack thickness and adjust to correct for wear on the packer plate, shank linkage, or seedboot tips.

During seeding:

- In the field, check that the cultivator is level.

- Periodically, check that the packer plates are intact, the hinge bolt is tight, and the roll pin is properly placed.